Leather aficionados are quite discerning when it comes to the quality of leather, realizing its’ importance in an accessory’s beauty and longevity. This begins with crafters’ commitment to sourcing from the very best leather distributors. Ultimately, our focus is on the end product, although we enjoy educating our clients and followers of bespoke as to the many levels it takes to get to final delivery. One step involves the tannery manufacturers who supply the beautiful finished hides prepared for the master leather crafters to build luxury leather travel bags, shoes or other accessories.

Leather designers such as Hermes, or Red Wing Shoes or Louis Vuitton or smaller firms like Beau Satchelle Bespoke, will only purchase high quality raw materials for their designs. This sourcing starts at premium leather tanneries. We would love to take our readers on a journey of the best tanneries in the world. Let’s begin with a well respected American company that is heralded as one of the top tanneries in the world: The Horween Company.

“We should take the best of everything; the best hides, the best oils, the best dyes and finishes – then we do whatever it takes to make that leather the best. The price goes on last, and if we cannot sell it for what it is worth, we should not make that leather.”

– Isidore Horween, Master Tanner and Founder, 1905 – 1948

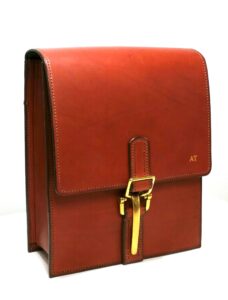

When a bespoke item is commissioned, handpicking prized leather is critical for guaranteeing superior products. With Beau Satchelle, as with many of our counterparts, sourcing of premium leathers, high-end thread tested to match leather’s superior strength, and substantial, durable hardware is chosen meticulously to ensure a well built product. Whether raw materials are sourced stateside or overseas, leather masters will never compromise their standards based on price and cheaply made leathers.

Within the world of leather tanneries, the name Horweeen is synonymous with excellence by being an evident leader in the tanning industry for over one hundred years of generational development to produce superior products.

The I. Horween and Co. began with founder Isadore Horween in Chicago in 1905, located in the meatpacking and rail district for the most obvious reason. To be in close proximity to raw materials. The tannery mainly manufactured cordovan razor strops which were used to sharpen straight razors for wet-shaving until safety razors were introduced that created a drastic popularity decline in straight razors which subsequently impacted leather strop use.

A most fascinating side note is the blossoming newfound interest in traditional wet-shaving. A growing group of purists swear the shave is higher in quality due to the blade’s cut being closer to the skin. There is a great sustainability argument as well, as these beautifully made straight razors become family heirlooms as opposed to the masses of disposable razors found in landfills.

In 1920, the company moved to its current location in Chicago’s Bucktown on the Chicago River to become a supplier for finely crafted shoes, boots, wallets and belts. To show the amazing versatility of leather, in the 1930s, the company developed mechanical leather for use in oil seats, gaskets and engine seats for automobiles. In addition, Horween developed and supplied water-resistant leather for footwear companies contracted for the U.S. Marine Corps during World War II.

Isadore’s sons, Ralph and Arnold, both accomplished college and professional football athletes, via a relationship with the coach of the Chicago Bears, were eventually contracted to produce the specialized leather cowhide footballs used by all NFL teams. The company embosses the leather with its distinctive pebbling and introduces a proprietary tanning process called Tanned in Tack ® which infuses the leather with a tacky feel to give football players a better grip. Not given the public recognition and adoration as the brands they service, but Horween supplies for the largest sporting goods manufacturers (for balls and gloves) including Wilson, Spaulding, Nike, and Adidas.

The uninformed will ask why are premium leather goods so expensive? To answer that question, let’s take a quick look at one part of the process: Horween’s tanning.

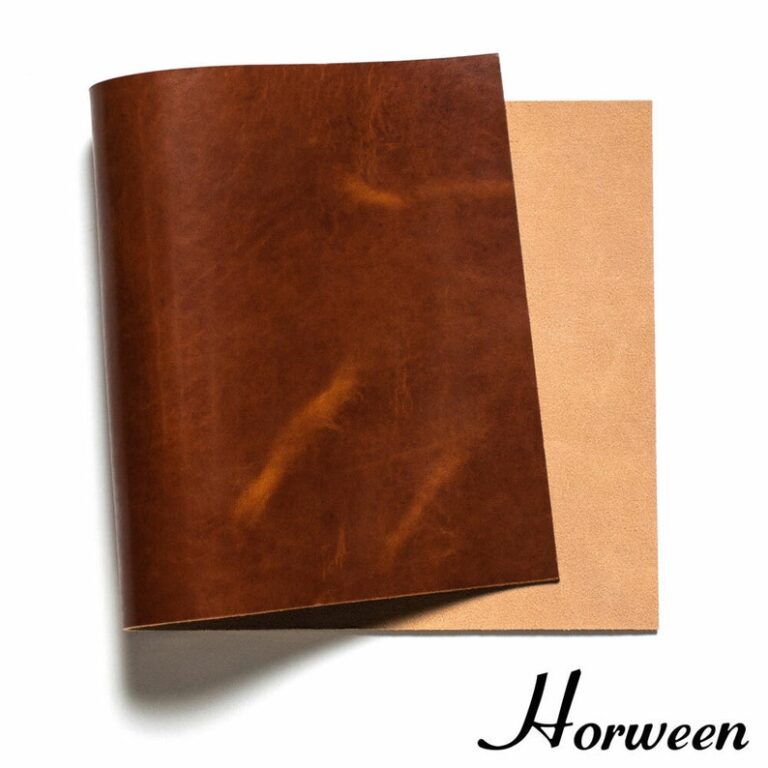

Horween’s signature leathers are the Shell Cordovan, Chromexcel and Essex. The Cordovan comes from the horse’s posterior sourced primarily from French-speaking Canada and parts of Europe where people still eat horse meat, which continues to dwindle in current times. Demand being higher than supply, the Horween is unable to accept new requests for Cordovan. In a nutshell, tanning is done in dye pits filled with Horween’s proprietary vegetable tanning solution made from tree barks for 30 days, then meticulously shaved, then returned into another tanning solution for 30 additional days. The final processes involve hand oiling, followed by resting for 3 months, then rewetting and finally shaved again.

Chromexcel, the original pull-up leather comes from cowhide are tanned with a chrome-based solution in large drums which give a baby blue tint, then the hides are re-tanned with a vegetable-based solution and then “hot stuffed” or conditioned with unrefined oils and greases.

Essex is vegetable tanned leather which uses the same traditional tanning extracts as the Shell Cordovan. The newest line of leathers developed, it took Horween nearly three years to produce this gorgeous leather along with its waxed versions. Because of its high oil content, accessories made from this leather will create a lovely patina over time.

Up to a half a year goes into Horween’s methodical systems, many done by hand, to produce a number of impressive butter soft or textured hides for designers and crafters globally.

Horween’s reputation for quality leather finishes has expanded their leather lines for production of golf shoes, work boots, cowboy boots, briefcases and leather jackets and coats and other leather accessories for J. Crew and Shinola Detroit. In addition, the tannery provides leather shells to the Timberland Company, Alden Shoe company, Cole Haan, Allen-Edmonds Shoe Corporation, Brooks Brothers and Johston & Murphy who all sell high-end footwear.

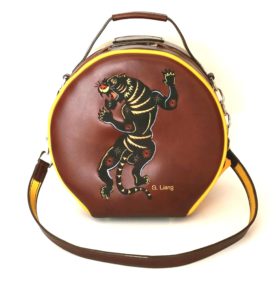

We have been fortunate to work with this exceptional leather on a number of commissioned projects. The leather is supple and quite versatile. Because of its durability, we love using it for travel bags’ interior or exterior that is used for carrying heavier essentials on a daily basis. It works well with travel bags that will get a good workout like the interior of a photographer’s bag transporting a variety of camera and video equipment. In addition, our Horween leather projects have included tote bags and wine carriers as a protective layer when carrying precious cargo. Horween leather will always be primary leather used in our bespoke offerings.

Interested in a bespoke accessory made from Horween Leather? Whether desiring a small accessory such as a tablet carrier or passport wallet or perhaps, a larger travel bag, the process starts by reaching out to us through our contact page, by email or by phone for a complimentary consultation. -AJ

Please take a moment to share your thoughts in the comment section or Twitter.

A huge thank you to the following sites for content:

Encyclopedia.com – Horween Leather Company

Buckleguy.com – Content and picture of Horween Leather

Thank you to the following photographers

Ben Hershey – Rawlings Baseball Mitt

Mark Adriane – Shinola watch

Dave Adamson – Wilson football on field

Jason Leung – Spaulding NBA Basketballs

5477687 – Barber’s Leather Strop Hanging on Wall

Legitagram – Cordovan Leather Shoes

SHARE POST

Customer Favorites