Fans of bespoke, will the made-to-order (MTO) or made-to-measure (MTM) fashion industry convince you to spend money as they begin to pivot more so towards sustainable wear?

Going into a little over a year and a half since the momentous month of March 2020, the world continues to adapt to the destructive rollercoaster effects of Covid-19. In the manufacturing world, the aftermath with regards to supply chain issues, shipping deliveries and labor shortages, is a phenomenon that is affecting companies both large and small.

Beau Satchelle had the opportunity to attend our first Detroit public networking and panel discussion hosted by Dbusiness, a regional media publication company covering the business climate in the Metropolitan Detroit area and the State of Michigan.

A peculiar personal side note: Although attending this event was welcomed and energizing, it was simultaneously a bit unnerving to be in a room full of people when you are so conditioned to working and living with a lock-down mode mentality.

DBusiness Magazine hosted its first Michigan Makers Breakfast Series Event on Tuesday, Oct. 12, at the historic Gem Theatre in downtown Detroit. Attendees enjoyed a strolling breakfast and the opportunity to network before listening to a powerful panel discussion regarding Makers businesses in Michigan. Featured panelists included our friend, Karen Buscemi, president and CEO of Detroit Sewn Inc.; Amy Peterson, CEO and co-founder of Rebel Nell; Brenna Lane, owner of Detroit Denim Co.; Bailey Zurawski, vice president of operations at Shinola; and Josh Hundt, chief business development officer of Michigan Economic Development Corp.

The main themes of the Makers panel:

1. Provided more evidence that the fashion manufacturing industry wants to move towards a more sustainable solution with less stored inventory and eventually massive amounts of textiles ending up in landfills.

2. After shutting down or reducing their manufacturing, these companies had the opportunity to redesign their inventory process. Basically focusing on sustainability methods versus scaling out-of-control and dealing with overproduction issues.

3. Small and Mid-sized maker businesses were essentially forced to rely on digital which in turn, created software tools to focus on custom built software including virtual fittings, and the ability to input measurements and other details for a custom product without being face-to-face.

4. An increase in collaborations with other American small and mid-sized designers.

5. There is a massive push to find suppliers in the U.S. and closer to home, solely to prevent being caught off guard again from major disruptions from economic events, political influences, social unrest or medical pandemics.

Unfortunately, that horse is out of the barn as countries, especially in Asia, Africa or South America, have the capabilities of producing cheaper parts (because of labor) that impacts the bottom line of products sold in the U.S.

6. Finding good workers interested in the industrial sewing/production industry.

7. Accepting the responsibility of taking care of their employees who are mandated to work in brick and mortar retail stores or the factory by providing sanitary conditions and support resources for mental health issues.

Imagine that clothing made prior to the mid 1800s was only handmade specifically for the person wearing it (hence the origins of the term bespoke). The invention of the sewing machine in the mid 1800s turned the garment industry on its head as mass production was introduced globally.

Pre-2020, many designers and manufacturers would offer consumers a variety of mass produced fashion items (ready-to-wear – RTW), trendy in nature and made for a particular season, presented in a multitude of colors, designs and embellishments readily available with a delivery date of days from their massive distribution centers of stored inventory.

There were a number of sustainable conscious fashion brands who made the decision to redesign their manufacturing process with made to order or made to measure to decrease waste. With this process, a customer selects a basic model and has a choice of standardized designs (i.e., color, measurements, body shape, personalization, etc.). This process has a longer wait time for consumers since the product isn’t created until time of order.

In 2021 we’re seeing dramatic growth among fashion brands who have pivoted since determining that made-to-order is good business to counter what occurred in 2020.

- To dramatically decrease warehouse inventory that eventually gets heavily discounted at the end of the selling season.

- To not rely solely on foreign supply chains.

- To end being so susceptible to overseas shipping and US mailing delays.

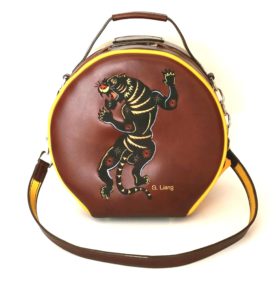

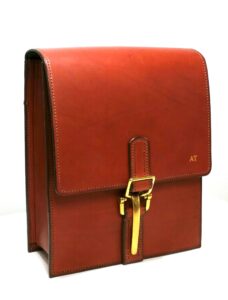

Fortunately, these effects have been minimal for Beau Satchelle as we offer bespoke – meaning total customization and our clients are educated and understand wait times can be weeks or months depending on the customization process. However, with some of our named collections (The Michelle, The Regina and so on) those bags are ‘made to measure’ allowing quicker turnaround times once a client decides on the base design, colors the interior and exterior leathers and thread and hardware finish.

By tweaking certain strategies or were new ideas implemented last year Beau Satchelle has:

1. Increasing our communication with our clients about the design and building updates including keeping our clients aware of supply lag times.

2. Pushing out finished product deadlines to head off any delivery issues that are out of our control.

3. Historically, we were quite lean when it comes to stocking raw inventory; however since some of our material orders are taking longer we are appropriately adjusting our numbers and are revamping our small studio storage area to accommodate more inventory.

4. To avoid complacency, we are continuously researching sources closer to home (plus backup vendors), while remaining authentic to the luxury product space which embraces both superb craftsmanship and superior materials. We have been quite successful in finding companies that manufacture high-end boxes and other packaging materials that meet our standards.

5. Educating our audience to understand that much of our premium cow leathers and hardware are sourced from European countries such as Italy and France and our exotics leathers (except for the Wild American Alligator) are ordered from hot climate countries where the skins are by-products of the country’s food supply. This in turn means that our timelines may be pushed up depending on the calendar of our suppliers.

6. We pride ourselves on making one bag at a time. What this means for a potential client is if we are unable to expedite your gifting deadline, our solution is presenting a Beau Satchelle luxurious boxed gift voucher that allows your recipient to schedule their experience in the designing and building of their bespoke leather carrying bag at a future date.

The Motor City’s manufacturing scene is steep in history to say the least as Detroit can boast being the birthplace of the modern moving assembly line, revolutionized by Detroit’s own Henry Ford. Beau Satchelle’s manufacturing roots hail from that past, yet also borrows from the past of hand-stitching artisans of Old World Europe. We are proud to be a part of a burgeoning growth of manufacturers in the Motor City that include a wealth of emerging and veteran talent in the fashion space who have come home to the art of customization.

-AJ

Please share your thoughts in the comment section below or on Twitter.

Thank you to the following photographers for the visual contributions:

Flaunter – Group of Models

Francois Le Nguyen – Sorting through tons of clothing “Clothing the Loop” social mission

Musuems Victoria – Gloves factory in Richmond VA

Alexander Kovacs – mass produced leather purses

Reuben Kim – Sewing in label

Charlota Blunarova – Designs on paper

Christian Erra – Bespoke Suitcoat

Ярослав Гринько – Leather sewn by machine

mO851 – Leather Hides

Mircea Ploscar – Rolls of Fabric

Lalit Kumar – Textile finishing Machines

SHARE POST

Customer Favorites